The Honda CR250 Fork Assembly is part 3 of the step-by-step rebuild for 1998-2001 Showa 47mm suspension forks.

You can find Part 1: Removal and Part 2: Inspection.

You Can Get Parts And Tools HERE! → https://amzn.to/4h4lDKq

Click here to open the Fork service specifications sheet in a new window.

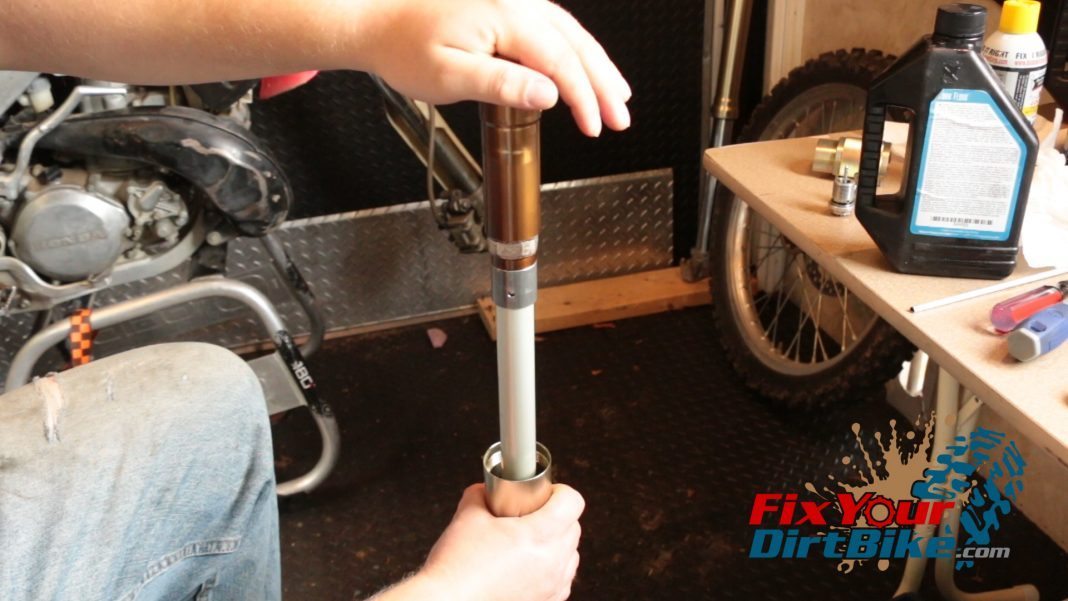

Fork Tube Assembly

- Step 41: Connect the fork tubes.

- Step 42: Place the guide bushing.

- Step 43: Place the backup ring.

- Step 44: Assemble the fork seal driver.

- Step 45: Seat guide bushing.

- Step 46: Place the oil seal.

- Step 47: Seat the oil seal.

- Step 48: Install the lock ring.

- Step 49: Place the dust seal.

- Step 50: Seat the dust seal.

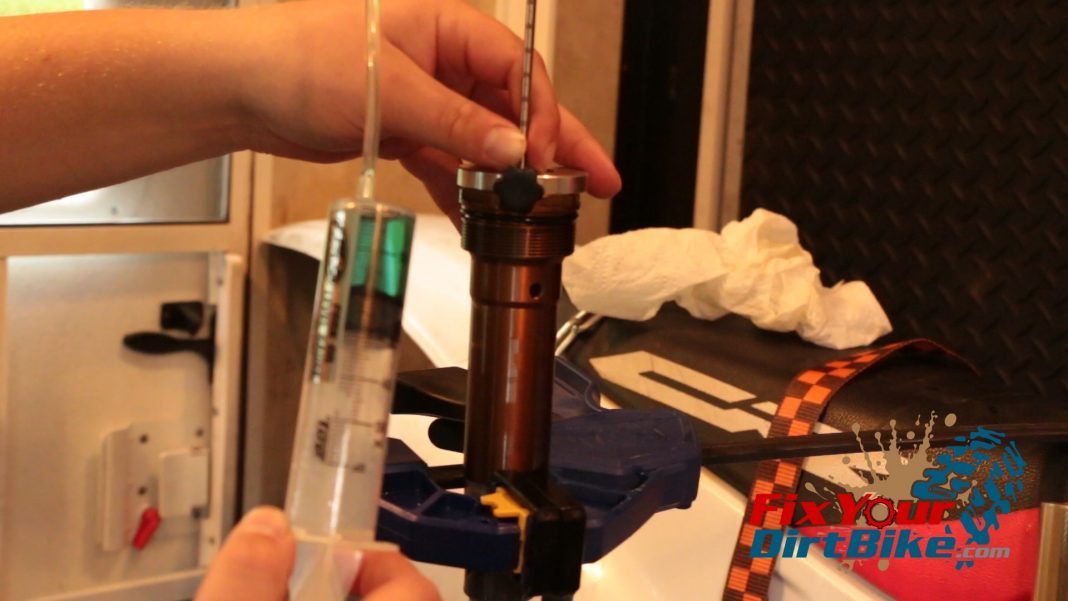

Fork Oil Level

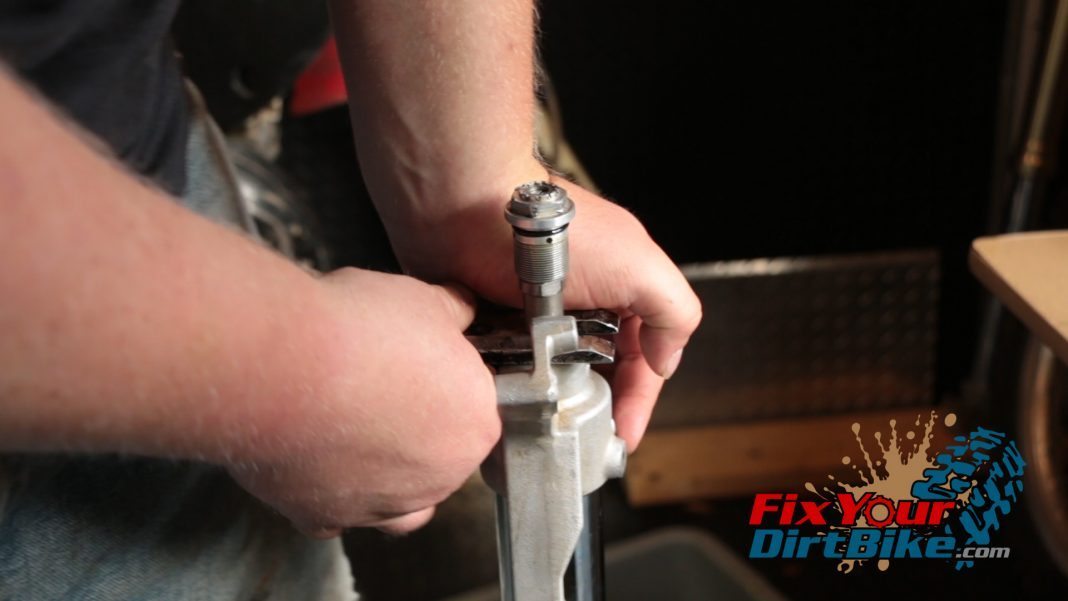

- Step 51: Hang the compression unit in a vertical vise.

- Step 52: Add fork oil – 180 ml.

- Step 53: Pump the piston.

- Step 54: Set the oil level – to 5-10 mm.

- The oil level is measured from the fork cap shoulder to the top of the oil.

- Step 55: Coat fork damper assembly with oil.

- Step 56: Seat fork damper assembly.

- Step 57: Torque fork damper assembly.

- 1997 – 87 ft-lb

- Lock Screw (1997) – 6 inch-pounds

- 1998-2001 – 40 ft-lb

- 1997 – 87 ft-lb

Bleed Compression Damper

- Step 58: Pump piston 100mm (4 in.) to void excess air.

- Step 59: Seat lock nut.

- Step 60: Make sure the rebound clicker is backed out.

- Step 61: Pump the rebound damper piston several times to bleed any trapped air.

- Step 62: Drain bled oil.

- Step 63: Remove the air bleeder screw (remember to

put it back!). - Step 64: Hang the compression unit upside down for 10 minutes to fully drain excess oil.

- Step 65: Pump the piston again.

- Step 66: Lay the compression unit flat and pump the piston in.

- Step 67: Release the piston. If the piston does not fully extend on its own, repeat the bleeding process.

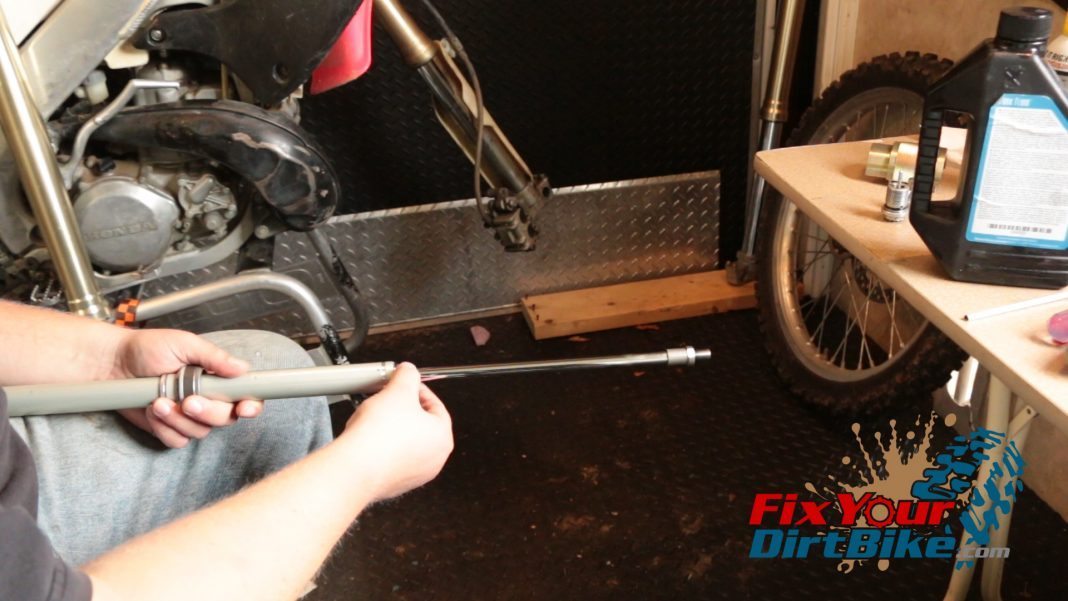

Damper And Tube Assembly

- Step 68: Install spring (Click here to ID your spring).

- Step 69: Install the compression unit.

- Step 70: Thread tube to cap.

- Step 71: Install rod stopper.

- Step 72: Install pushrod, making sure it is lined up.

- Step 73: Install the center bolt in the piston.

- Step 74: Correct the thread gap – 1.5-2mm.

- Step 75: Tighten the lock nut to the center bolt.

- Step 76: Torque damper (compression unit)

lock nut.- Lock Nut – 16 ft-lb

- Step 77: Remove the rod stopper.

- Step 78: Torque center bolt to the tube. – 51 ft-lb

- Step 79: Unscrew the cap again.

- Step 80: Add oil to the tube. The spring rate determines how much oil to put into the fork tube.

- Step 81: Reassemble the fork cap for the last time.

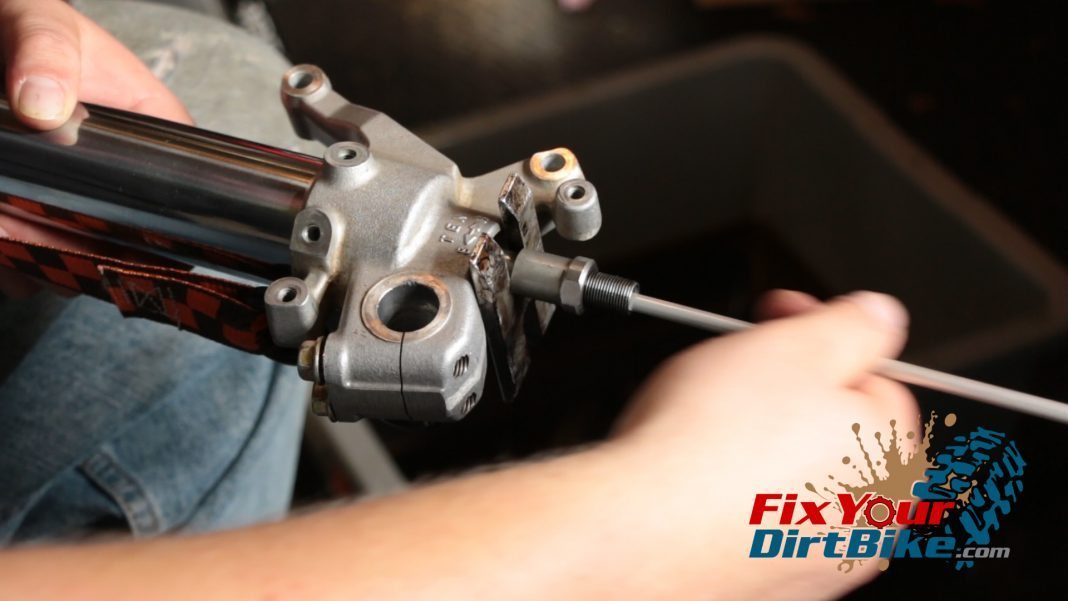

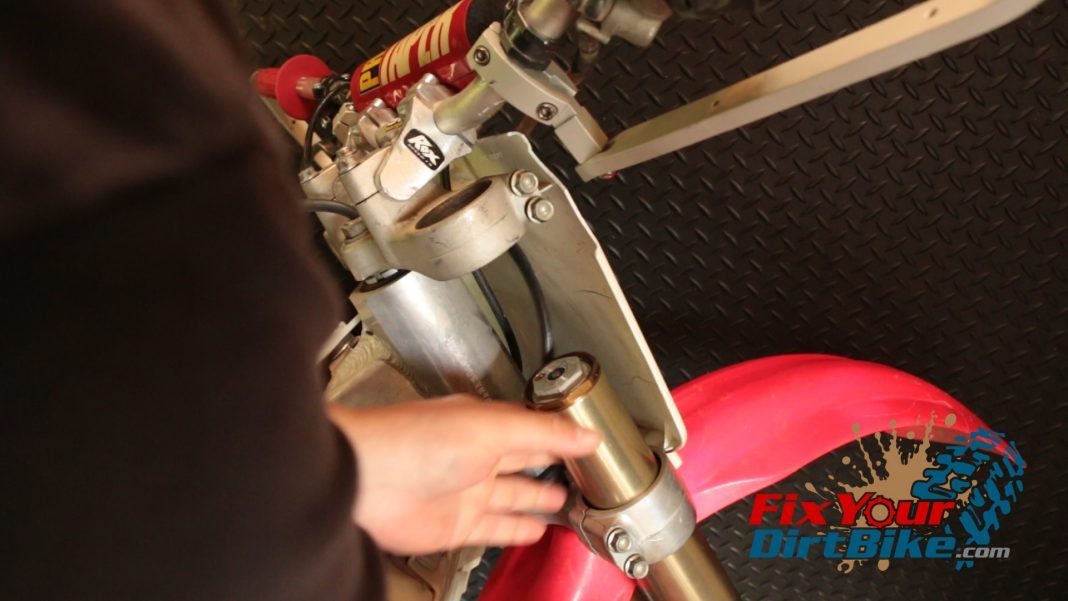

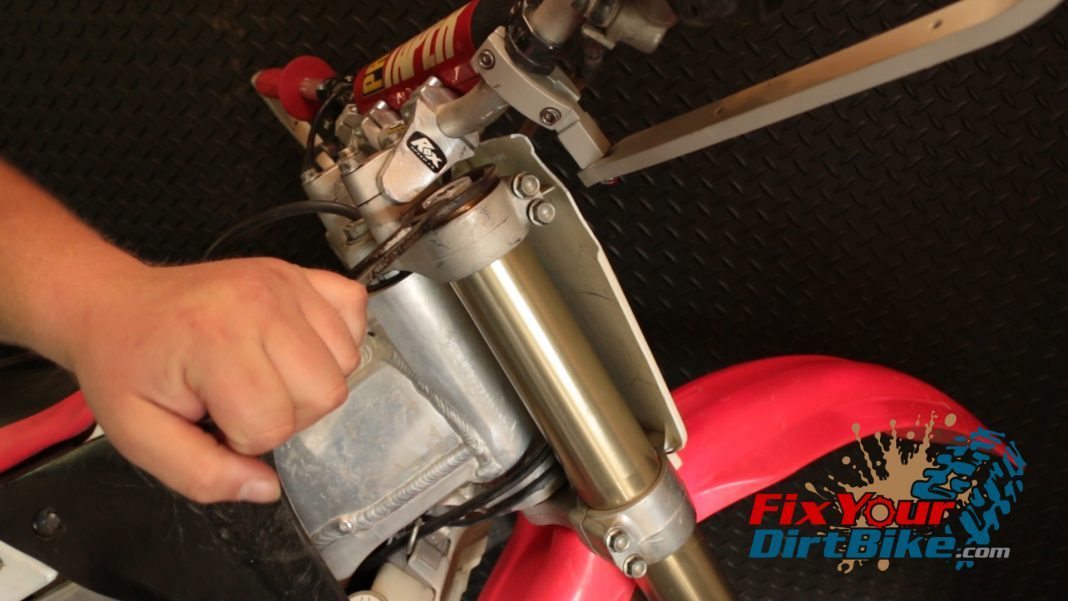

Fork Installation

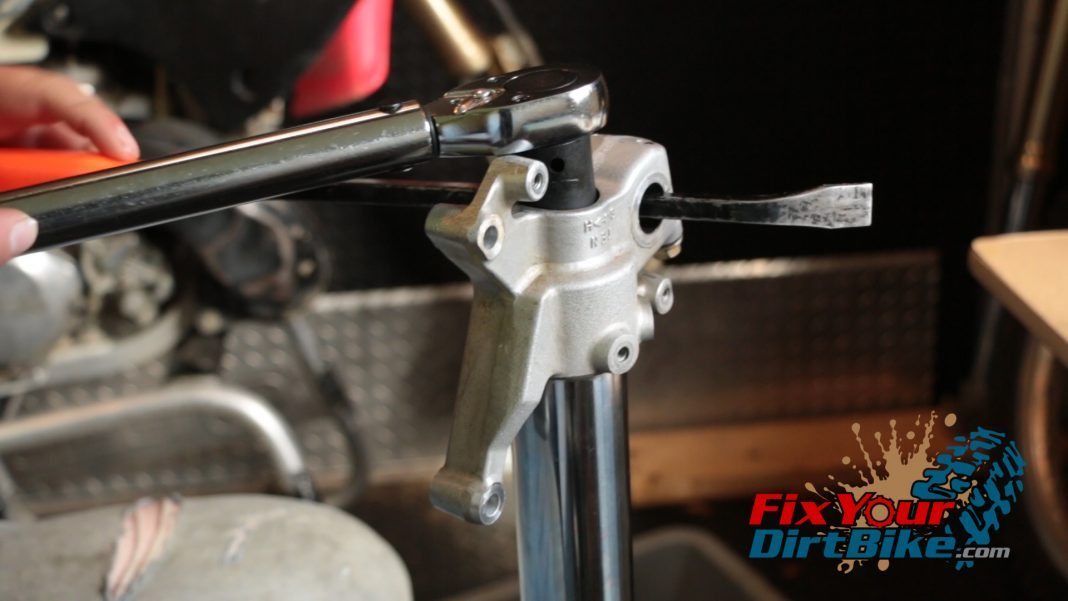

- Step 82: Install your fork on the triple clamp.

- Step 83: Torque lower bridge bolts only – 15 ft-lb.

- Step 84: Torque fork cap.

- 1997 – 40 ft-lb

- 1998-2001 – 22 ft-lb

- (Torque upper bridge bolts – 16 ft-lb)

If you have any questions or comments, please leave them in the comments or on our Facebook page!

Keep Your ’97-’01 CR250 Running Right!

- Service Specification

- Clutch Replacement

- Carburetor Service

- Engine Top End

- Engine Bottom End

- Brakes

- Exhaust

- Front Suspension

- Rear Suspension

- Wheels & Tires

- Kickstarter Inspection

- External Shift Linkage