How To Install The Cylinder On Your 97-01 Honda CR250

The Tools You Will Need

The Tools You Will Need

- Piston Holder

- Motion Pro Torque Wrench Adapter → https://amzn.to/4g2Moy8

- Foot-Pound Torque Wrench → https://amzn.to/3DOqm4B

- Inch-Pound Torque Wrench → https://amzn.to/4j9LDpC

- 4mm Hex Socket

- 17mm Socket

- 14mm Socket

- 12mm Socket

- 8mm Socket

- Lithium Grease → https://amzn.to/3ChhKTB

- Shop Towels

- Safety Glasses → https://bulltru.com

The Parts You Will Need

- New ’97-’01 Honda CR250 Bottom End Gasket Set → https://amzn.to/42jJKkd

- New Right Cylinder Cover Gasket → See Above

- New Cylinder Alignment Dowels → https://amzn.to/3DVxPPm

Pre-Service Notes

- I recommend opening the Service & Torque Specs in a new tab for easy reference.

- If you need parts and tools, make sure to buy them here! → https://amzn.to/4h4lDKq

- Pictures with captions are below after step b.

- If you need any help don’t hesitate to ask!

Cylinder Installation

- Double-check the cylinder bore and mating surfaces for cleanliness.

- Apply lithium grease to the exhaust valve pinion joint.

- Install NEW alignment dowels on the left side of the crankcase.

- Install your new gasket.

- Place your piston holder, and rotate the crankshaft so the piston skirt rests against the holder.

- Double-check the piston rings are seated against the locating pins and position your cylinder.

- Hold the cylinder as level as possible with the piston and compress the top ring against the alignment pin.

- The cylinder should slide right over the ring.

- Repeat with the second ring.

- It Is Extremely Important That You Do NOT Rotate The Cylinder!

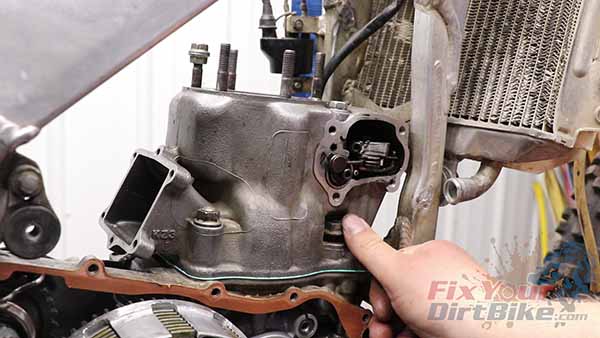

- Remove the holder and align the exhaust valve drive shaft.

- The drive shaft opening should face the rear of your bike.

- Lower the cylinder onto the studs.

- Thread the cylinder mounting nuts finger tight.

- Tighten the exhaust linkage pinion bolt hand tight and check the exhaust valve’s operation by pulling and pushing on the governor.

- Begin torquing the nuts in the same pattern as removal.

- Turn the nuts ¼ turns at a time, making as many passes as necessary to reach torque.

- Torque the cylinder mounting nuts to 29 ft-lbs.

- Remember, when using the torque adapter, you will NOT need to compensate for length if the adapter remains at a right angle to your torque wrench.

- Loosen the exhaust linkage pinion bolt, turn the valve all the way counter-clockwise, and check that the flap valve is open.

- Torque the pinion bolt to 48 in-lbs.

- Install the right cylinder cover with a new gasket.

- Torque the valve stopper bolt to 141 in-lbs.

- Torque the left exhaust valve cap to 115 in-lbs.

- Torque-check the head studs and install the right crankcase cover.

Torque Specifications

- Cylinder Mounting Nuts 29 ft-lbs.

- Pinion Bolt 48 in-lbs.

- Valve Stopper Bolt 141 in-lbs.

- Left Exhaust Valve Cap 115 in-lbs.

← Part 11: Piston Installation

Part 13: Cylinder Head Installation →

Keep Your ’97-’01 CR250 Running Right!